TRANSMISSION & AXLE

Construction machinery customers from the mining sector all have one topic in common. The reliability of their machines is essential, since nothing in this industry is as expensive as long downtimes. The stress on the individual drive train components can be very high due to the heavy loads on construction machinery.

Especially when having high loads and bad road conditions, the stress in the drive train is quite high.

Timely service intervals and preventive maintenance measures can protect against failure and premature wear of vehicle parts and prevent unplanned visits to the workshop with additional costs due to consequential damage.

High quality spare parts is the best prerequisite for a long-functioning gearbox. We rely on our many years of experience and selection of quality products from our suppliers.

In order to provide professional maintenance of your gearbox or axle, you will find below a selection of manufacturers in which we have specialized.

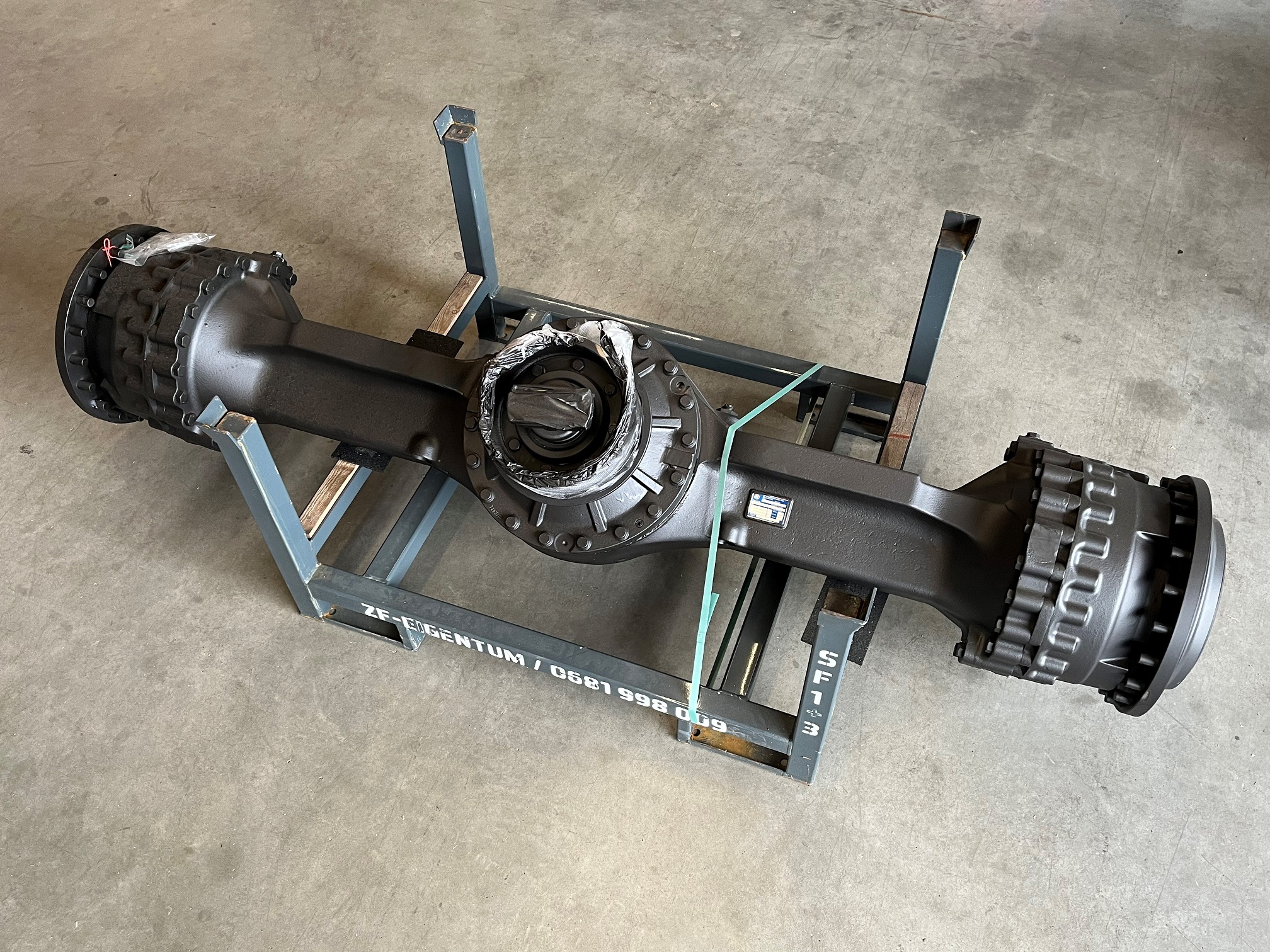

Axle

- Caterpillar

- ZF

Transmission

- Allison

- Caterpillar

- ZF

ENGINE

Industrial engines are often subjected to difficult challenges and rough conditions.

Whether in construction machinery, agricultural machinery or in forestry, industrial engines are in great demand everywhere in these areas.

Especially the maintenance of the diesel engines is a very important point for a long engine life. Regular service largely prevents engine damage and the resulting costly repairs.

In case that an engine needs to be serviced or overhauled, we have specialized in the following manufacturers.

Engine Parts

- Caterpillar

- Detroit Diesel

- Terex

Filter

- Donaldson

DRILLING MACHINE PARTS

For open-pit mining operation, we are the official dealer for Saudi Arabia in the field of supplying spare parts for drilling rigs from the manufacturer Nordmeyer SMAG.

The SBM 86 is an advanced rock drilling technology for all geological formations in an open-cast mining environment. To optimally adapt to its work environment, the SBM 86 can be built based on crawler or wheel carriages, depending on the distance of the work sites.

Each carriage system features large ground clearance, high-stability four-point supports, and a compact, agile design for superior and safe manoeuvrability within its operation locations.

All SBM86 large hole drilling rigs feature PLC-controlled automation, a parallel-edge driving mechanism, high-performance drives, automated levelling and drill rod handling, a large-scaled drill boom with tolerance free adjustment, a drill guidance system with a displaceable suction hood and an infinite regulation of feed and rotation speeds.

We can offer the complete range of parts for the SMAG drill rigs of the type SBM 86 and SBM 86R. Whether engine spare parts, hydraulic controls or drill rods, we provide our customers with the necessary parts.